AI-enabled Facility Management and Controlling System(FMCS) for Factories

Intro

The project is my bachelor thesis sponsored by Foxconn.

Facility Management Control System (FMCS) is a monitoring system for a factory′s cooling water, electricity, compressed air, etc. This system enables factory monitors to receive a real-time resource usage and gives them the essential information to adjust the resource input, which reaches better outcome within limited energy usage. With the development of machine learning technology,the factory now hopes to build a smarter FMCS which can not only monitorenergy usage but also predict the resource dispatch. In this way the factory can achieve the optimization in resource management and reduce energy cost.The core problem is how we use the limited dataset or other ways to achievethe prediction function of FMCS.

Final Design

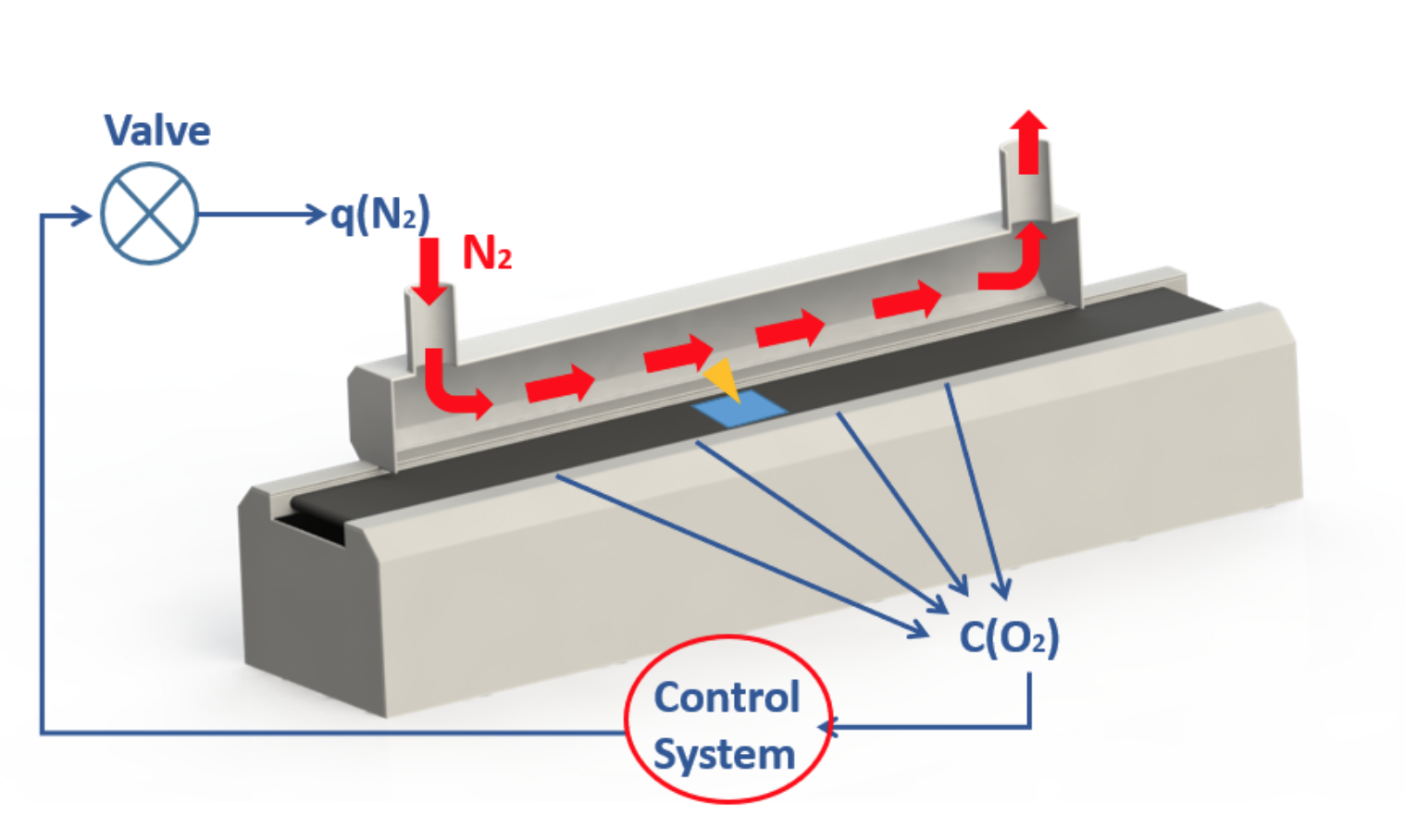

Considering that FMCS is a giant blue print, our project is just a tiny part of it. Our design problem is specific to a machine called reflow oven, which is quite an essential unit in the assembly line because it is used primarily for reflow soldering of surface-mount electronic components on printed circuit boards. Reflow ovens are designed to work in an oxygen-free atmosphere to avoid oxidation, which is harmful to the quality of soldering. As a result, nitrogen is a common inert gas used by humans to minimize oxidation of the surfaces to be soldered. In this project, we are expected to control the flowrate of nitrogen through our algorithm and monitor through an interactive web interface.

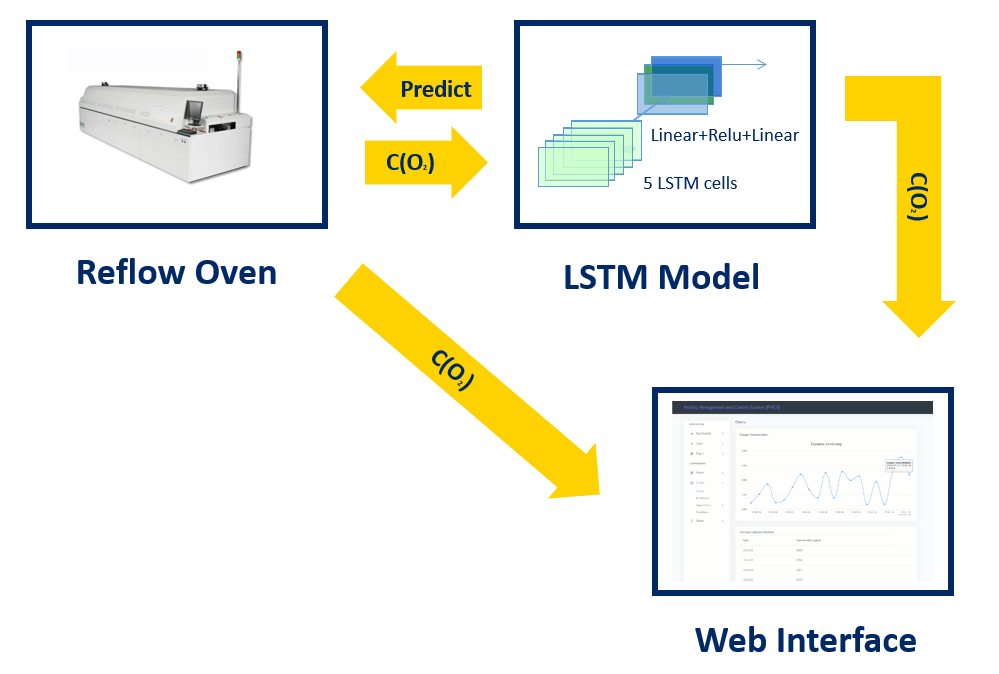

By the end of this project, our team build a deep learning model with fair training accuracy and construct a website which supports dynamic chart and table rendering. Also, our team build a mini reflow oven, which is for the purpose of demonstration on the EXPO. The flow chart of our project is shown below.

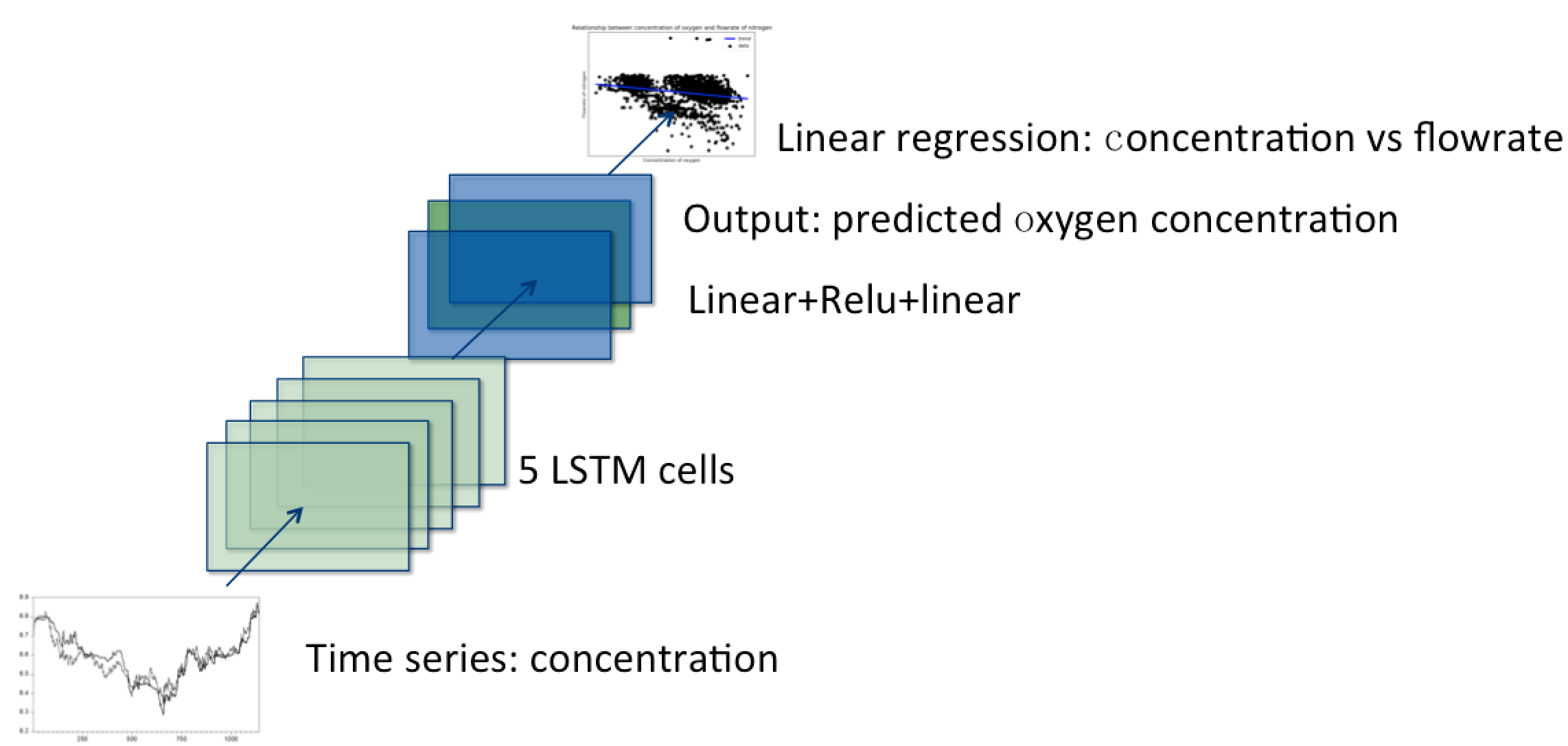

We decided to use recurrent neural networks embedded with long-short time memory to implement our final algorithm model. The architecture is shown below.

We first generate time series of history data of oxygen concentration fluctuation from reflow oven and then put them through a five layer LSTM model. Then we output the predicted value of oxygen concentration at next time point. Then we implement a simple linear regression model to find the relationship between nitrogen flowrate and oxygen concentration.

After training, we reach accuracy of 72% on our testset. For validation, our algorithm was installed within Foxconn factories and it performend well enough to maintain oxygen concentration within limited range.

Expo

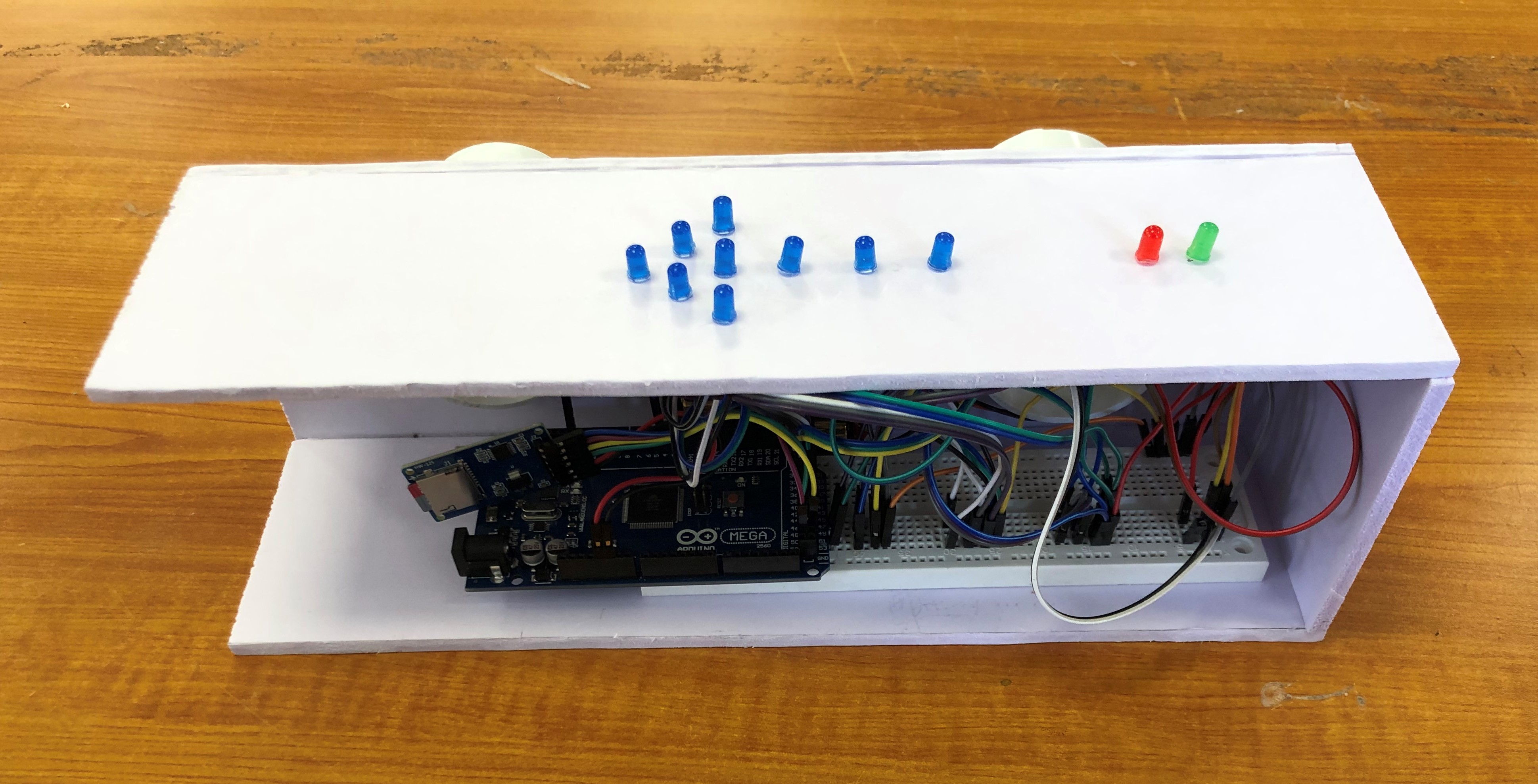

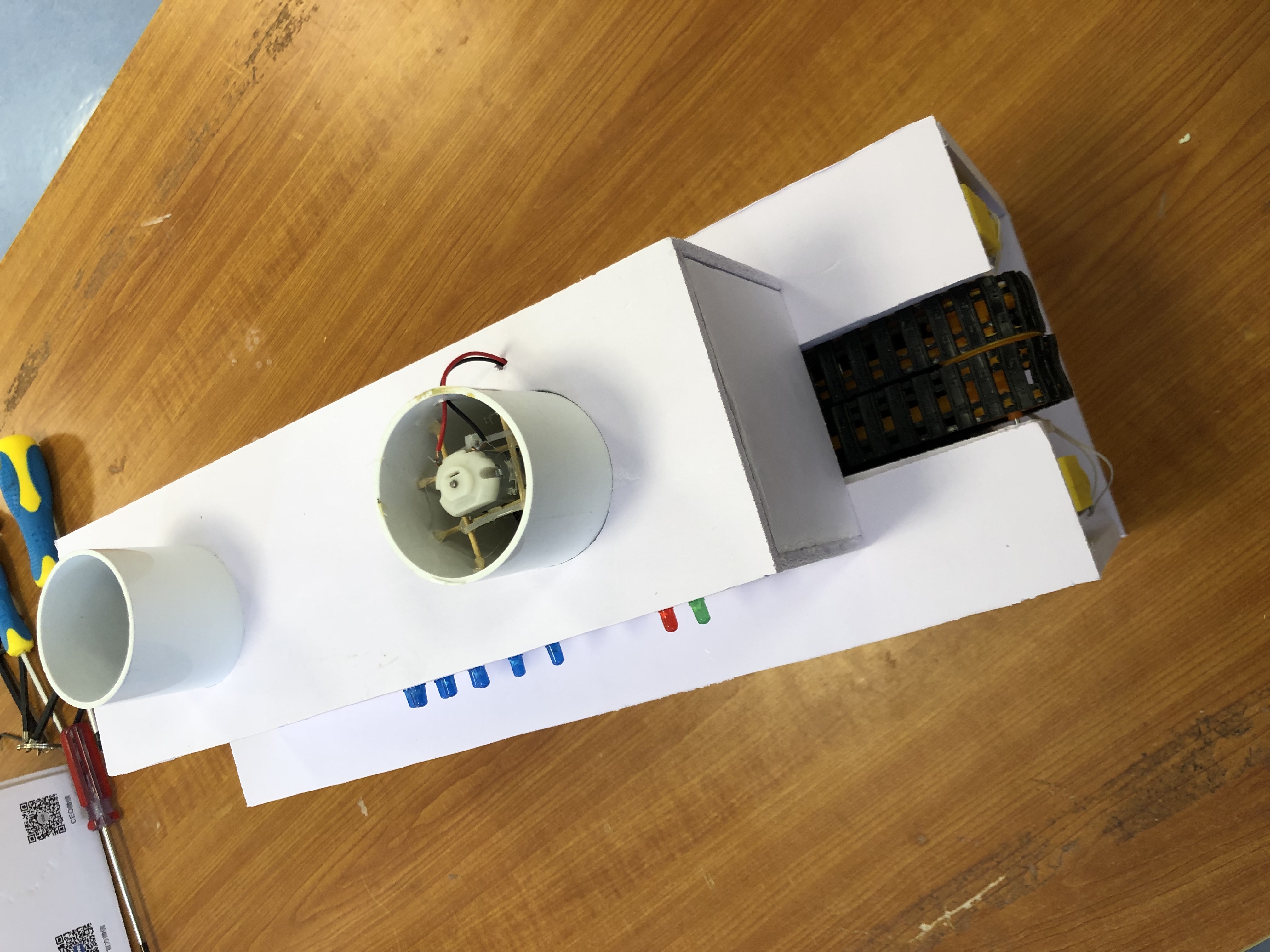

For final demonstration, we built a reflow oven model to indicate the flow of nitrogen and the level of oxygen shown below.

The model could monitor the oxygen concentration as well as simulate a warning system.

|

|